In pipe smokers' minds, traditional pipes are made from briar. However, it has not always been the case, and different materials are still used for pipe manufacturing.

A little bit of history:

Introduced in France in 1560 by Jean Nicot, tobacco was snuffed or chewed, and then smoked by rolling the leaves on themselves. It is only later that briar was widely adopted. First occidental pipes were made from terracotta, an affordable and easily shapable material. However, these pipes were not considered as durable over time because they were very fragile.

There are many workshops in Saint-Claude since the Middle Ages because lots of wooden goods were created, such as pipes made from local woods. Boxwood, beech wood or cherry wood were the most commonly worked. However, pipes made from these woods did not last for long. Not heatproof enough, they changed tobacco's taste. It is only in 1852 that briar was finally recognized for its properties.

Briar's advantages:

- Lightweight, it is possible to keep the pipe at the corner of the mouth without getting tired. You have to know that briar of a good quality is more lightweight.

- The great ability to absorb humidity, for even more comfort when smoking.

- Great resistance against the heat for a longer life.

- A neutral taste, to enjoy even more the aromas of the tobacco.

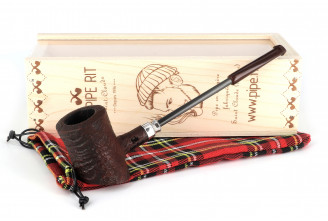

Very quickly, Saint-Claude's pipes manufacturers gave up local woods for briar and, nowadays, almost all pipes are made from briar. Other pipes are mainly made from meerschaum or morta.

Choosing a briar pipe:

Now that you know why briar is used for pipe manufacturing, discover how to choose the right pipe.

Share this article to your favorite social networks!